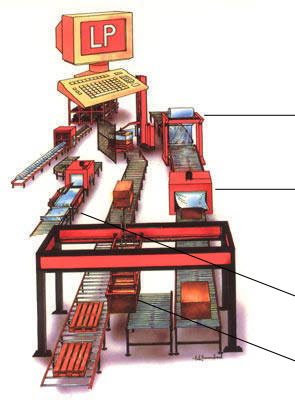

How the machines operate

In our shrink wrapping machines normal recyclable Polyethylene (PE) is used. When the film is exposed for heat the film shrinks tight around the product. This gives a good protection and a nice looking package.

Banderolls The film is wrapped or folded around the product. If you want a totally sealed package this is attained by lamination or side sealing stations. When the film is wrapped around the product you can choose to shrink it or not to.

Shrink tunnels After the film is wrapped around the product it is transported through the well isolated tunnel. Exact temperature and regulated airflow guarantee good shrink result. Our technique minimizes the loss of heat.

L-sealers A folded film is used, and are feed around the product and are totally sealed. A bag has been created around the product which can be shrinked or not.

Stackers Products are put automatically on a pallet from a conveyor or the opposite way around. Lifting is made by vacuum or mechanically graspers.

Edge cushion banderol Puts a strip of miniwell around the product, for example flooring, plaster boards etc., before wrapping of the film and shrinking. The miniwell is sealed but a label or by hot melt.

Bag sealing machines A film is folded around a ”tube” and are totally sealed. The machine can be automatic or semi automatic.